5 Ways to Reduce Industrial Fires

6/1/2020 (Permalink)

To avoid falling victim to industrial fire, there are several things you can do to prevent an industrial fire outbreak.

To avoid falling victim to industrial fire, there are several things you can do to prevent an industrial fire outbreak.

Industries lose millions of dollars to fire yearly. Between 2012 and 2015 alone, about 37,910 industrial properties were gutted by fire, according to the National Fire Protection Agency (NFPA).

To avoid falling victim to industrial fire, there are several things you can do to prevent an industrial fire outbreak.

First, identify the most common causes of industrial fires. These are

- Combustible Dust Fire

- Hot Work Fire

- Flammable Liquid and Gas Fire

- Equipment and Machinery Fire

- Electrical Hazard Fire

1. Combustible Dust Fires

When dust or fine material is mixed with air in a particular concentration, it explodes. The severity of a combustible dust explosion can bring down an entire facility.

To prevent a combustible fire, carryout dust inspection, housekeeping, testing, and control program on your facility.

Be on the lookout for dust residues in open and hidden areas. In the presence of an ignition system, avoid cleaning methods that generate dust clouds. Open flames should be controlled.

2. Hot Work Fires

Any work that requires high heat or generates flames is regarded as hot work. Examples of hot work are soldering, welding, heat treatment, grinding, and more.

Hot works can be prevented by:

Training personnel and ensuring they adhere strictly to safety measures.

Remove flammable materials from operation areas.

Ensure a safety professional is on-site to supervise operations.

3. Flammable Liquid and Gas Fires

Flammable liquids and gases should be handled with utmost caution to prevent an explosion.

Flammable liquid and gas fire can be reduced by keeping them far away from heat or ignition sources. Store hazardous materials, according to OSHA. Provide safety protective equipment, like bodysuits, goggles, shoes, etc.

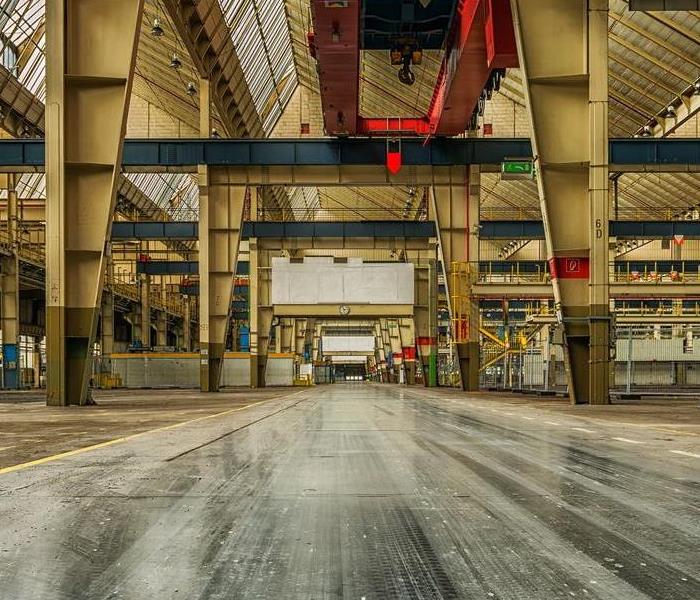

4. Equipment and Machinery Fires

Equipment and machinery fires are common amongst equipment poorly operated, installed, or maintained, or operated. Hot work and heating equipment are mostly causes of equipment and machinery fires, if not properly maintained.

As mentioned earlier, heavy-duty hot work equipment requires immense training on equipment operation, as well as the need to focus on handling and maintenance of equipment.

The surrounding environment should be kept clean at all times. Sometimes, overusing a machine can make it react badly and may lead to fire hazards. Prevent machines from overheating.

5. Electrical Hazard Fires

A spark from an overloaded circuit, poor wiring, or defective material can raze a whole facility near combustible dust, flammable liquids, and gases.

Therefore, avoid overloading electrical circuits. Turn off a machine or equipment when not in use. OSHA and NFPA recommend the use of antistatic material.

Inspect your facility for combustible dust and other hazardous materials and clear equipment area of such.

Take on fire safety measures in your facility. Engage your employees with fire safety training to educate them on proper fire safety equipment operation and safety procedures.

24/7 Emergency Service

24/7 Emergency Service